The World of High-Tech at Your Fingertips: Fast, Easy, and Smart

Wide Range of Security and Protection System Equipment

In today’s world, security and safeguarding of property and lives have become fundamental needs of every society. Have you ever thought about how advanced equipment can bring peace of mind to you and your family? In our online store, we have provided the most comprehensive and best security and protection solutions for you.

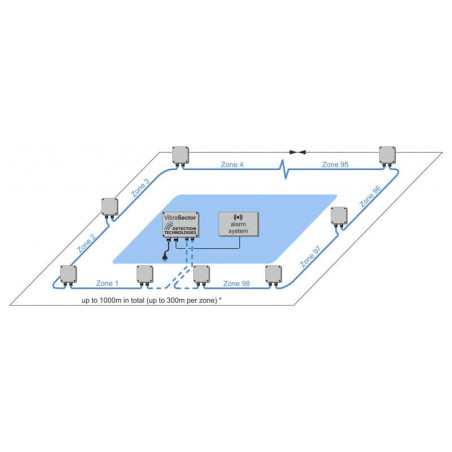

From CCTV cameras and surveillance systems to access control devices and perimeter protection radars, we cover all your needs. With our licenses for monitoring and security software, you can easily supervise any location and prevent unfortunate incidents. Welcome to a new world of security—where every moment is monitored and every threat is quickly identified. Join us and bring security to your premises by choosing the best!

57 products