Reliable Technology And Unmatched Performance

• The Cummins® K38 series rugged engine and world class Stamford alternator powered diesel generator set

• Proven technology with mechanical simplicity of Cummins PT fuel system.

• Advanced in-cylinder technology and 2P2L Cooling system to meet latest emission norms without any after-treatment device

• Smart aesthetic and superior finish

• Compact in size with optimum power to weight ratio

Environment Friendly Power

• Class defining technology engine is designed to meet stringent exhaust emission tests as per revised MoEF norms, thus offering environment friendly power.

• The Cummins® diesel generator sets are available with the lowest noise levels in its range

Lowest Operating Cost and Comprehensive Warranty

• Highly reliable and durable product

• All elements are designed to work together to maximize efficiency even at part loads, offering the advantage of lowest operating costs.

• 500 Hours/ 1 year service interval

• Industry acknowledged best-in-class comprehensive warranty on the entire package including rubber components

Single Source Power Assurance

• All the major components – the engine, alternator, control system and canopy are designed, manufactured and tested by Cummins India.

• Best and largest customer support network in India,

• Capable of providing round-the-clock service and spares support

• All these things put together, Cummins® offers you SINGLE SOURCE POWER ASSURANCE

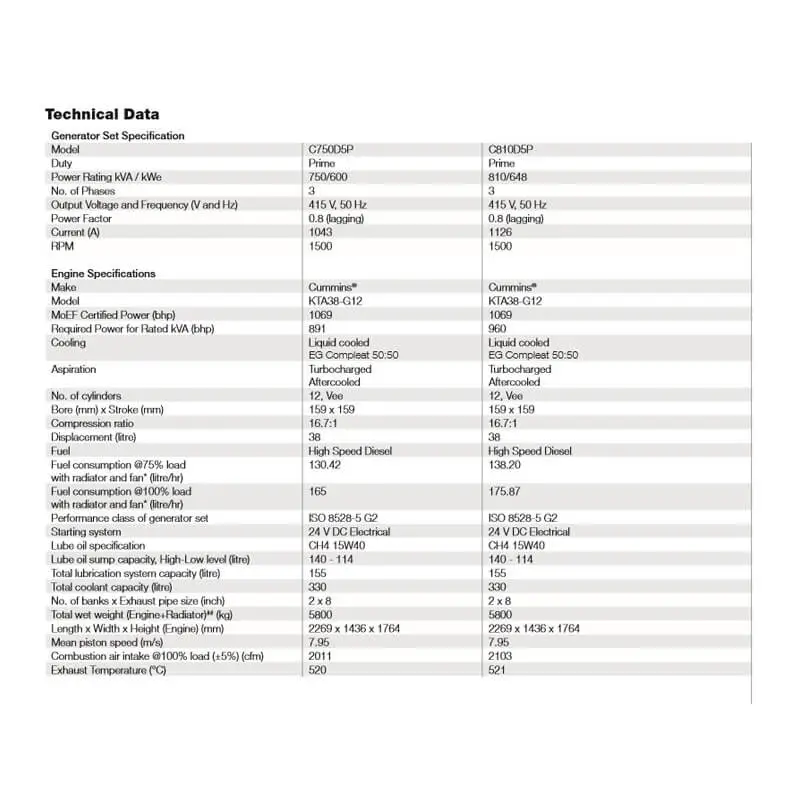

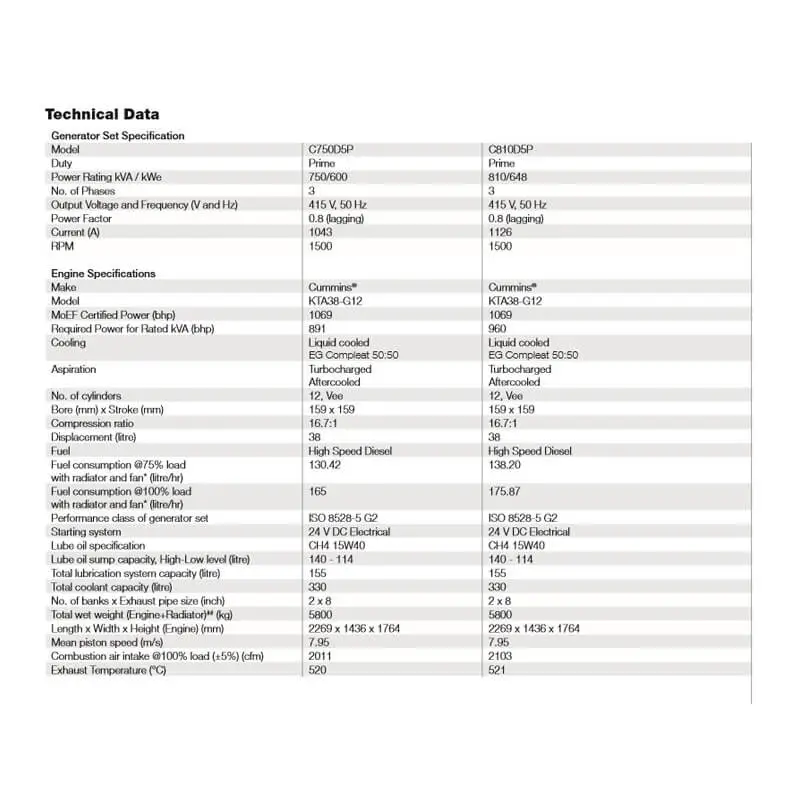

Engine

• Cummins® K38 series, 12 cylinder, In-line 4 stroke, radiator cooled engine

• Highly stable and reliable design with square engine

• Well designed air handling system with

— Dry type, Replacable paper element air cleaner with restriction indicator

— Outboard aftercooling with 2 pump 2 loop system

— Optimised turbocharger for increased altitude capabilities

• Best in class fuel economy with

- PT fuel system with Electronic Step Timing Control (ESTC) injectors which smoothly stabilise engine speed under load with A1 class Electronic governing

- Dual fuel filter system: Pre filter including water separator and Water In Fuel (WIF) sensor and main filter

• Standard integral set-mounted radiator system, designed and tested for 50°C ambient temperatures

• Full flow spin on lube oil filter

• Plate type lube oil cooler

• First fill of lube oil and coolant

• Electrical starter motor with soft start engagement feature

• Battery charging alternator

• 2 X 12 V DC battery

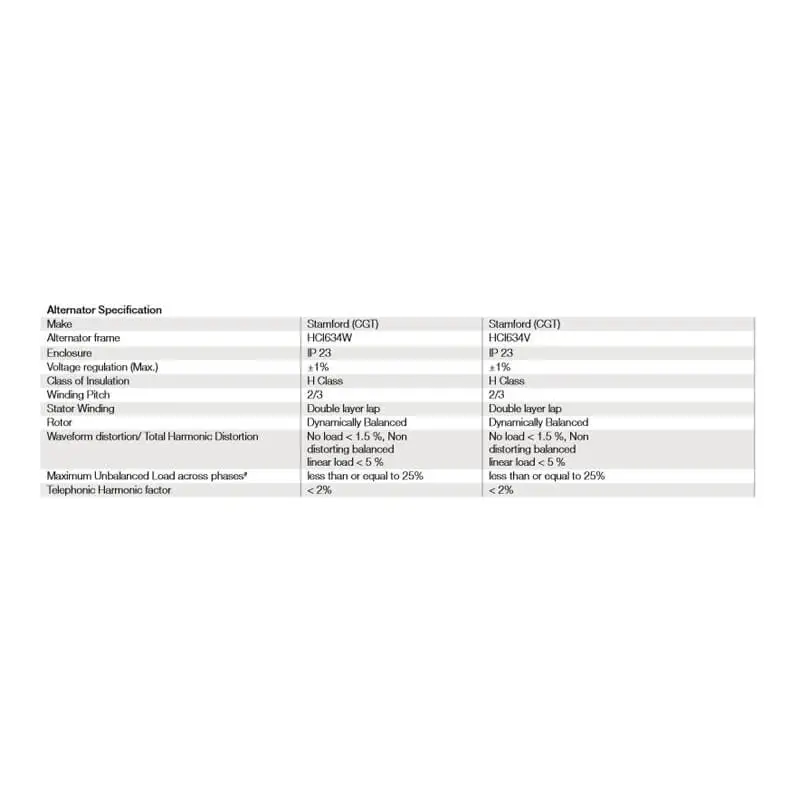

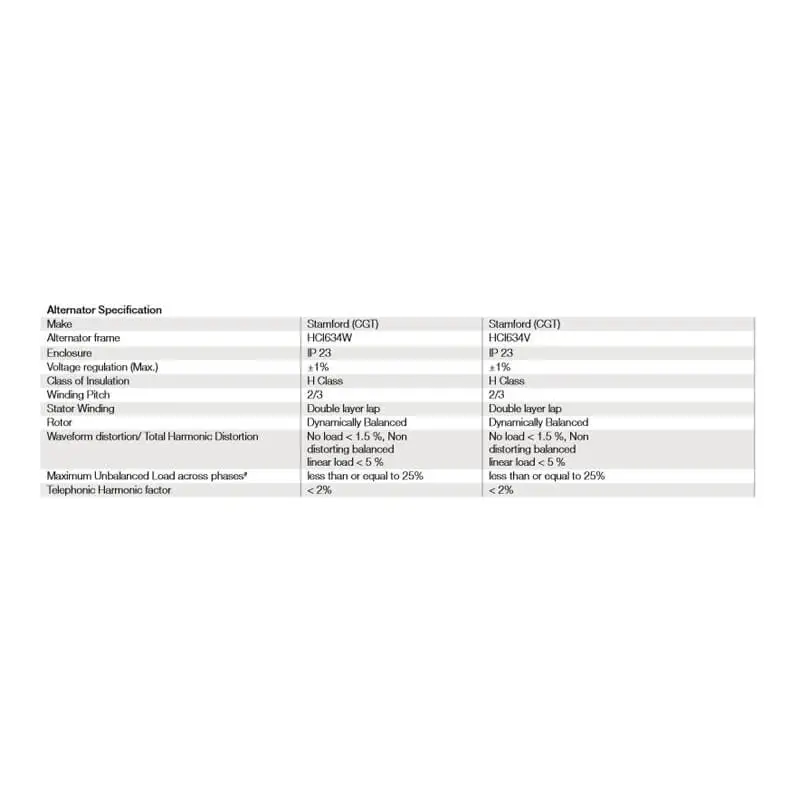

Alternator

• Stamford HC4 alternator frames from cummins Generator Technologies

• Brushless type, Screen protected, Revolving field, Self excited alternator conforming to IS/IEC 60034-1

• PMG standard

• Better motor starting capability

• Best in class efficiency

• Compact design with sealed bearings for longer life and lesser maintenance

• Impregnation on all wound components for better mechanical strength

Control Panel

Control panel is manufactured with 14/16 gauge CRCA sheet and is powder coated for weather-proof and long lasting finish. The control panel consists of the following parts:

• Power Command 3.3 Controller

• Aluminum bus bars with suitable capacity with incoming/ outgoing terminals

• Indicating lamps for ‘Load ON’ and ‘Set Running’

• Instrument fuses duly wired and ferruled

• Air Circuit Breakers (ACBs)/Moulded Case Circuit Breaker (MCCB) of suitable rating with overload and short circuit protections

PowerCommand 3.3 features

The PowerCommand control system is a microprocessorbased generator set monitoring, metering and control system with LCD display designed to meet the demands of today’s engine driven generator sets

• Intuitive operator interface which includes LED backlit LCD display with tactile feel soft-switches & generator set status LED lamps

• Integrated digital AVR for shunt or PMG excitation with torque matching.

• Digital electronic governing with temperature compensation and smart starting.

• SAE J1939 interface to Full Authority Electronic (FAE) engines

• Remote start-stop

• Engine metering: Oil pressure, High coolant temperature, Low coolant level, Battery voltage, Engine speed and hours.

• AC Alternator metering: L-L Voltage and L-N Voltage, Current (1 and 3 phase), Volt-Amperes (phase and total) and Frequency.

• Utility/AC bus Metering: L-L Voltage and L-N Voltage, Current (1 and 3 phase), kW, kVAR, Power factor, kVA (three phase and total), and Frequency.

• Paralleling Control Functions: Digital frequency synchronization and voltage matching, Isochronous kW and kVAr load sharing controls, Droop kW and kVAr control, Sync check, Extended paralleling (Peak Shave/Base Load), Load govern control, Load demand control.

• AC Alternator protection: Over/Under voltage, Over/Under frequency, Over current, Short circuit and Loss of AC sensing.

• Data logging: Engine hours, Control hours, Engine starts and upto 10 recent fault codes

• Engine Protection: Low lube oil pressure, High/Low coolant temperature, Over speed, Battery Over/Under/Weak Volts, Fail to crank/start, Cranking lockout, Low fuel level, Sensor failure.

• Utility/AC bus protection: Over/Under voltage, Under frequency and Phase rotation

• Paralleling protections

• Control Functions: Start-stop with configurable time delay, Real time clock for fault and event time stamping, Exerciser clock and time of day start/ stop, Configurable glow plug control, Configurable cycle cranking, Load shed/ dump as per configurable priority

• 12 and 24 Volt DC operation

• Sleep mode

• Programmable I/Os (4 inputs and 4 outputs), expandable with AUX101/102 modules

• Self-Configuring PCCNet network

• Modbus interface (RS485 RTU)

• InPower compatible (PC based service tool)

• Certifications - meets the requirement of relevant UL, NFPA, ISO, IEC, Mil Std., CE and CSA standards

Telematics Offerings

• Fault Code Alerts on Email & SMS

• Advisory Services

• Fuel Level Monitoring on Email & SMS

• Multiple Gensets Central Monitoring

• Automatic Reports Generation

Silencer

• Hospital grade silencer with rain cap suitably optimised to meet stringent noise emission standards laid down by MoEF / CPCB

Mounting Arrangement

• Engine and alternator are mounted on a common MS fabricated base frame with AVM pads.

• Base frame with integral fuel tank is provided with drain plug, air vent, inlet and outlet connection, level indicator and provision for cleaning

Optional

• Engine: Coolant Heater, Lub Oil heater, Heat exchange, No cool

• Control Panel: - PC3.3

- Bargraph For PC3.3 Panel with kW, Power factor, Frequency,Current, Voltage

- Remote HMI

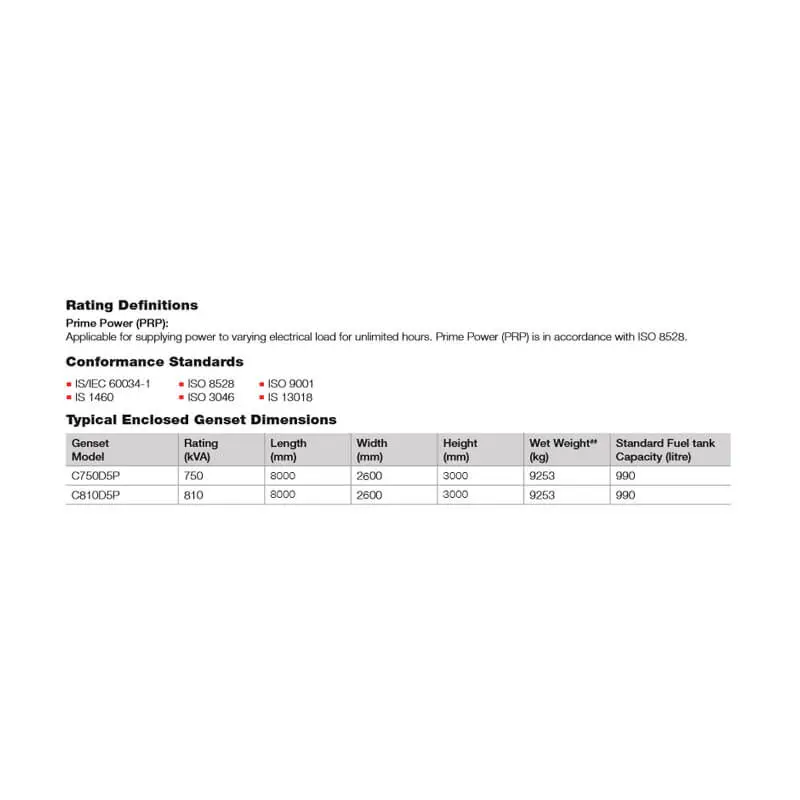

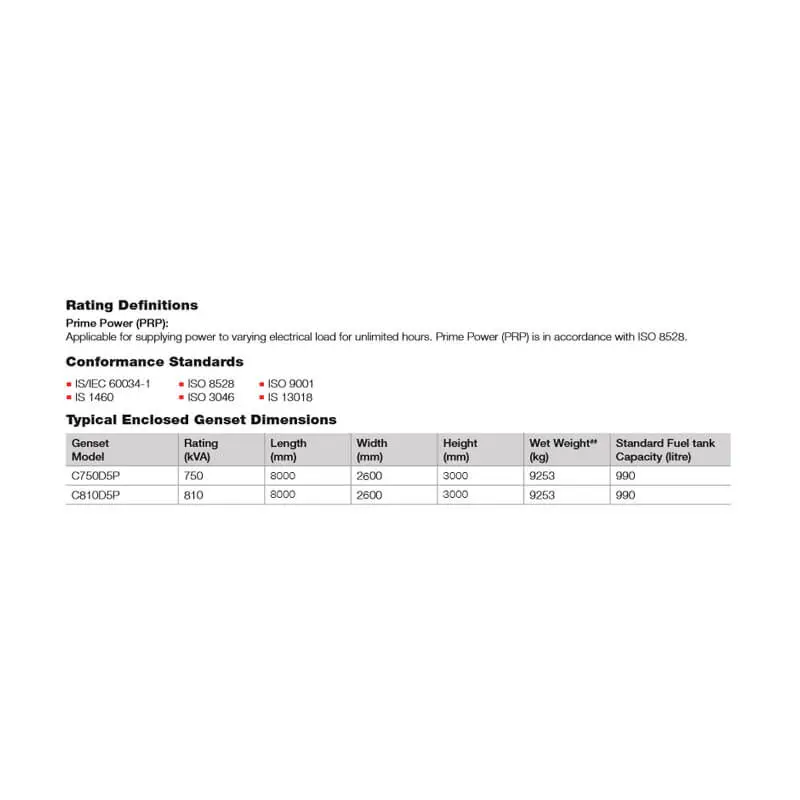

Acoustic Enclosure

• Specially designed to meet stringent MoEF/ CPCB norms of 75 dBA @ 1mtr at 75% load under free field conditions

• The acoustic enclosure is made of CRCA sheets in munsel green shade and a structural/ sheet metal base frame painted in black.

• High quality noise absorbant and fire-retardant grade acoustic Insulation material (P.U. Foam) complying to IS 8183

• Two point lifting for easy handling at customer site

• Designed to have optimum serviceability

• Air inlet louvers specially designed to operate at rated load

• Made on special purpose CNC machines for consistency in quality and workmanship

• 11 tank pretreatment process and UV resistant Powder Coating of all parts to withstand extreme environment

• Use of special hardware for longer life

• Flush styling - no projections

• Fluid drains for lube oil and fuel

• Fuel filling arrangement inside the enclosure