Such generators are used in industries and places such as hospitals, commercial buildings, oil and gas industries and other places that need stable electricity in emergency situations.

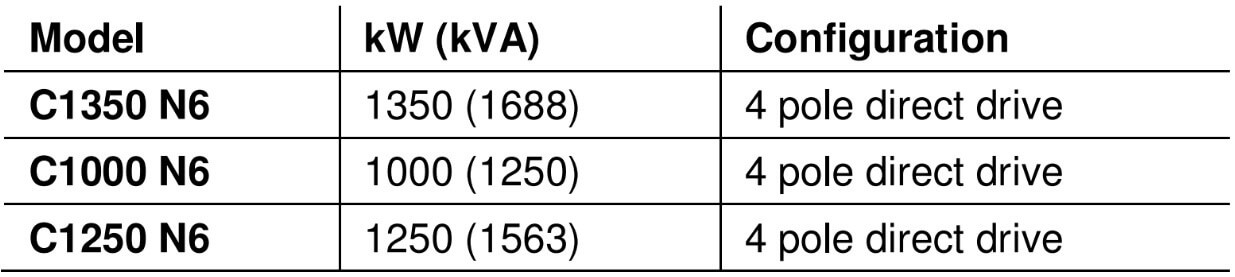

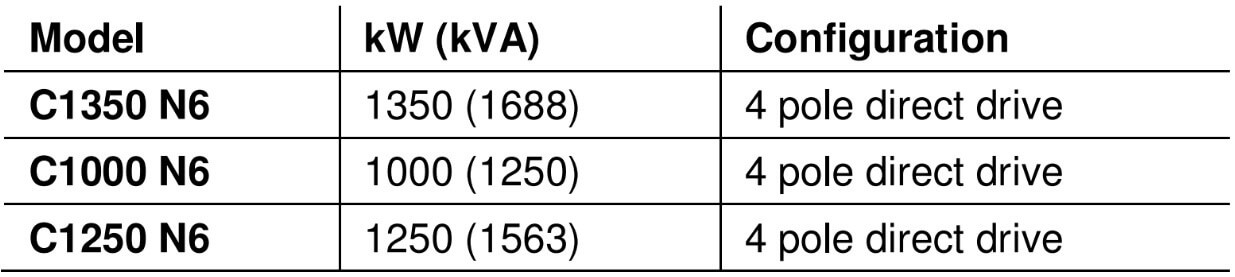

This Cummins gas generator set is a fully integrated power generation system utilizing state of the art technology that results in optimum performance and efficient use of fuel for Standby applications.

Features

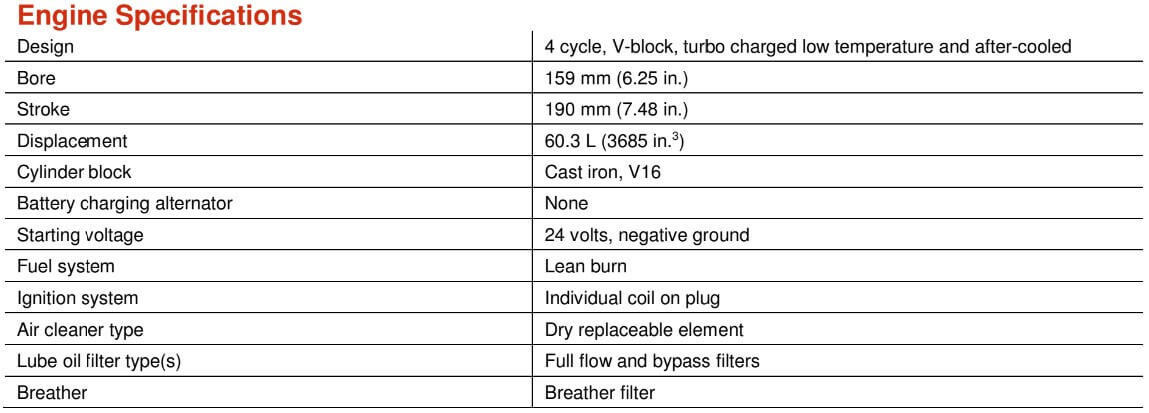

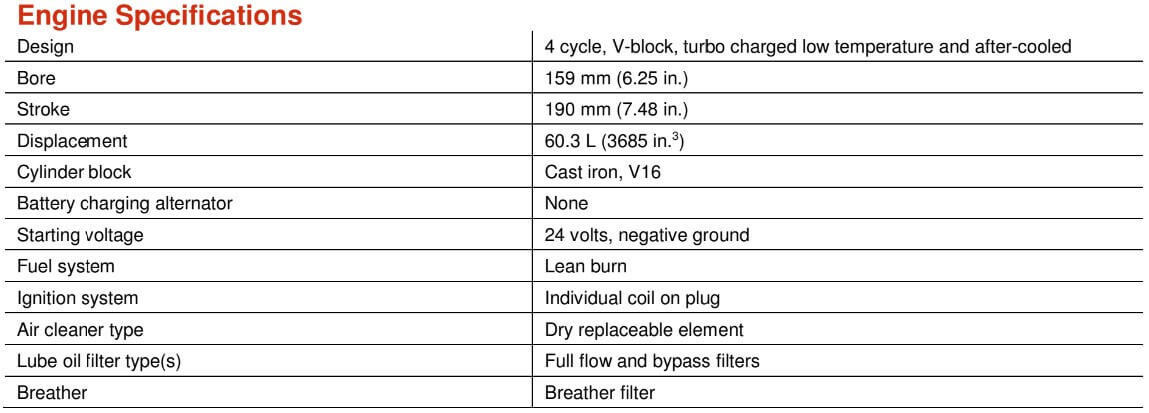

Exhaust Emissions - Lean burn technology provides exhaust emissions levels as low as 1 g/hp-hr NOx.

Cummins Heavy-duty Engine - Rugged 4-cycle lean burn gas combustion engine utilizing full authority electronic engine management and monitoring.

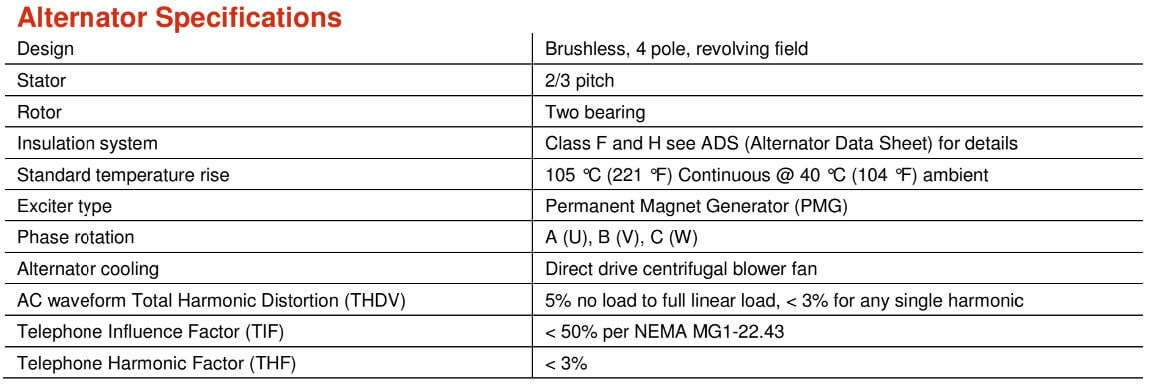

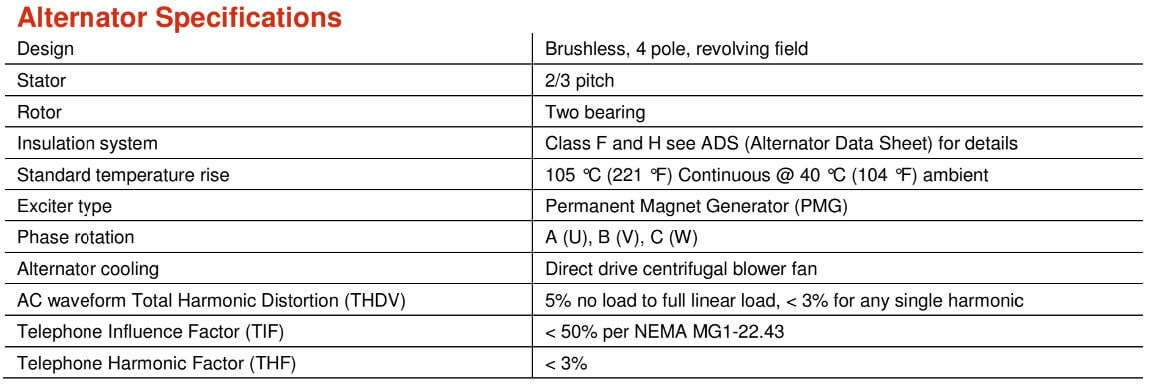

Permanent Magnet Generator (PMG) - Excitation system offers enhanced motor starting and fault clearing short circuit capability.

Alternator - Several alternator sizes offer selectable voltage and temperature rise with low reactance 2/3 pitch windings; low waveform distortion with non-linear loads, fault clearing short circuit capability, bearing and stator RTDs, anti-condensation heater, class F or H insulation (see alternator datasheet for details). Mechanically strengthened for use on utility paralleling with unreliable grid.

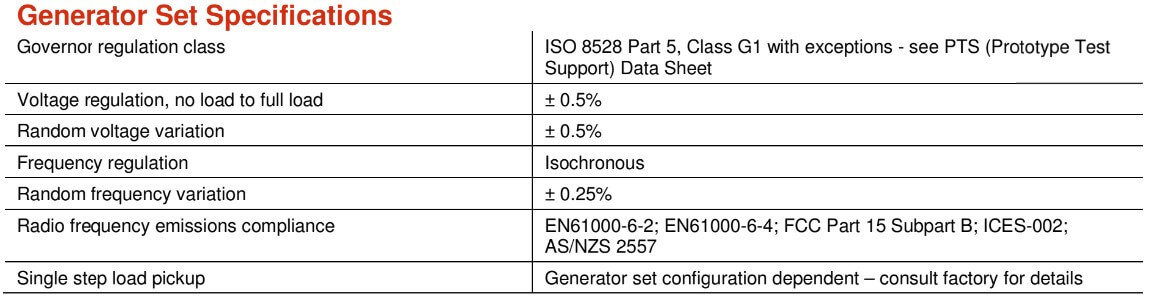

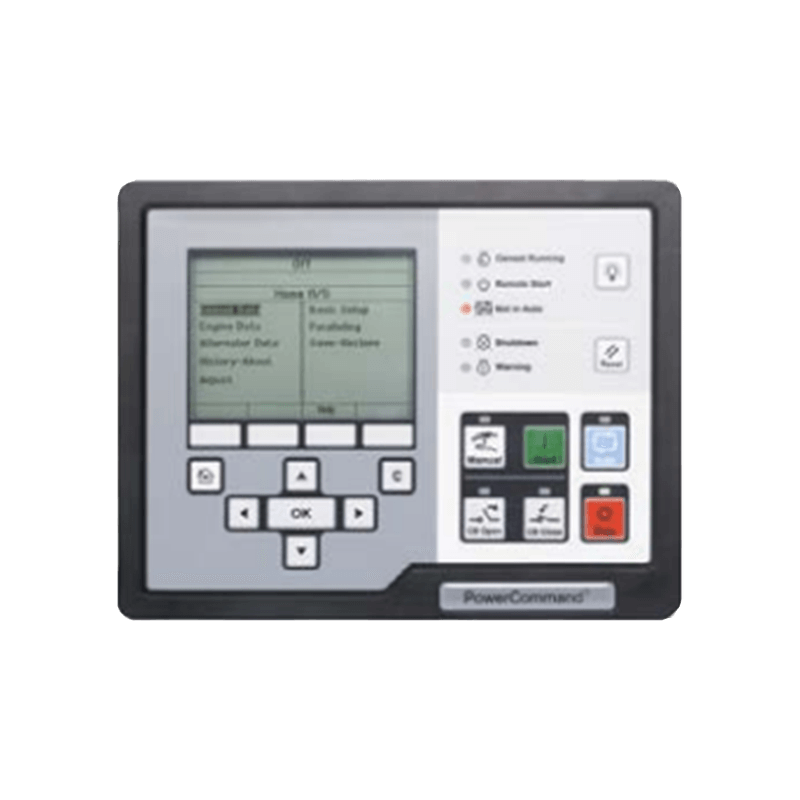

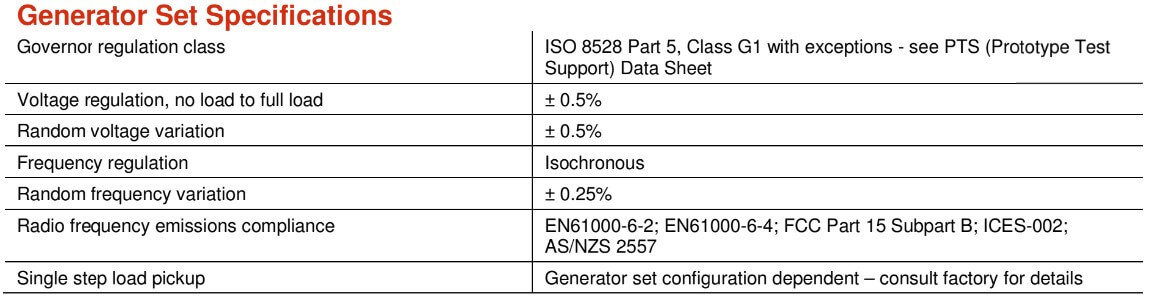

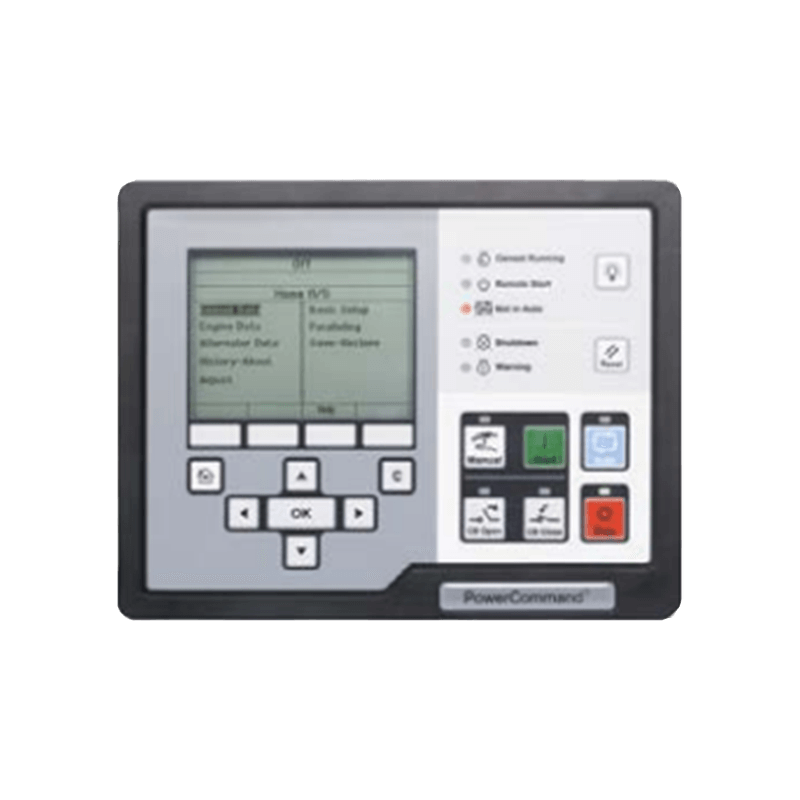

Control System - The PowerCommand 3.3 generator set control is standard equipment and provides total genset system integration including full paralleling capability in grid or load share mode, precise frequency and voltage regulation, alarm and status message display, AmpSentry protection, output metering, auto-shutdown at fault detection and a user interface panel installed onto the genset. Optional remote operator panels are also available.

Cooling System - The generator set is equipped with the capability to interface with a remote radiator or heat exchanger.

Warranty and Service - Backed by a comprehensive warranty and worldwide distributor network that can provide all levels of service from replacement parts to performance guarantee programs.

PowerCommand 3.3 Control System

The PowerCommand control system is a microprocessorbased genset monitoring, metering and control system designed to meet the demands of today’s engine driven gensets. The integration of all control functions into a single control system provides enhanced reliability and performance, compared to conventional genset control systems. These control systems have been designed and tested to meet the harsh environment in which gensets are typically applied. Major features include:

- AmpSentry protection providing a full range of alternator protection functions matched to the alternator provided.

- Extended paralleling (peak shave/base load) regulates the genset real and reactive power output while paralleled to the utility. Power can be regulated at either the genset or utility bus monitoring point.

- Digital frequency synchronization and voltage matching.

- Isochronous load share.

- Droop kW and kVAr control.

- Real time clock for fault and event time stamping.

- Real time clock for start/stop to initiate a test with or without load, or a Base load or Peak shave session.

- Digital voltage regulation. Three phase full wave FET type regulator.

- Genset/Engine monitoring and protection.

- Utility/AC bus metering and protection.

- Modbus interface for interconnecting to customer equipment.