CyberRow CRS211AS product is a high-precision Inrow air conditioning unit specifically designed for cooling telecommunications, IT, and computer systems. This device is designed as a row unit and can be easily installed between server racks, making it ideal for data centers and IT rooms with hot and cold aisles. This German-made Inrow unit boasts a variety of features and is one of the most high-tech cooling systems for data centers in the world. The CRS211AS air conditioning system is an ideal solution for creating optimal temperature and humidity in various environments. This device has a total cooling capacity of 20.2 kW and an airflow rate of 4,600 cubic meters per hour, providing high efficiency in maintaining optimal temperatures.

The World of High-Tech at Your Fingertips: Fast, Easy, and Smart

Specifications of Stulz CyberRow CRS211AS Inrow

Outstanding Technical Specifications:

Total Cooling Capacity: 20.2 kW

Sensible Cooling Capacity: 19.4 kW

Return Air Temperature: 33 degrees Celsius

Return Air Relative Humidity: 30%

Optimal Performance:

Air Velocity: 3.5 m/s

Sound Power Level: 83.9 dB(A)

Sound Pressure Level at 2 meters: 64.0 dB(A)

Compressor Specifications:

Compressor Type: EC Compressor

Power Consumption: 7.3 kW

Compressor Speed: 120 RPM

Evaporation Temperature: 8.0 degrees Celsius

Coefficient of Performance (COP): 2.76 kW/kW

Fan Features:

Fan Type: K3G225

Number of Fans: 5

Power Consumption per Fan: 0.8 kW

Maximum Speed: 2860 RPM

Other Specifications:

Device Weight: 220 kg

Dimensions: Height 1,950 mm, Width 300 mm, Depth 1,200 mm

Refrigerant Model: R410A

Power Supply: 400 volts / 50 Hz / 3 phase / N / PE

The complete range of air conditioning technology – from one source.

For over 50 years, the STULZ family-run company has been synonymous with precision air conditioning at the highest level.

Our solutions for the air conditioning of businesscritical applications and sensitive systems have made us a leading company in our industry.

Whether for data centers, industry or communication technology, the STULZ portfolio has a tailor-made cooling solution to suit your requirements.

We guarantee adherence to our uncompromisingly high requirements and quality standards both at our factory in Hamburg and all our production sites around the globe. Moreover, we work hard not only to satisfy our customers’ individual wishes, but also to make sure our air condition ing solutions offer maximum energy efficiency and a minimal CO2 footprint

Our portfolio extends from traditional room cooling and High Density Cooling to chillers, air handling units and container modules, all the way to micro data centers, service, and our self-developed monitoring software. An all-embracing quality assurance system monitors all the details in development, production, implementation, and service.

Today, STULZ has a presence in more than 140 countries. STULZ GmbH has 23 subsidiaries and eleven production sites in Europe, India, China, and North and South America. We also have partner agreements with numerous sales and service partners on every continent. Our network of highly qualified specialists is a reliable guarantee of the highest standards.

The combined wealth of our experience, values, performance and service is what defines us and is especially valued by our customers. Air conditioning solutions – custom tailored and from one source:

ONE STULZ. ONE SOURCE.

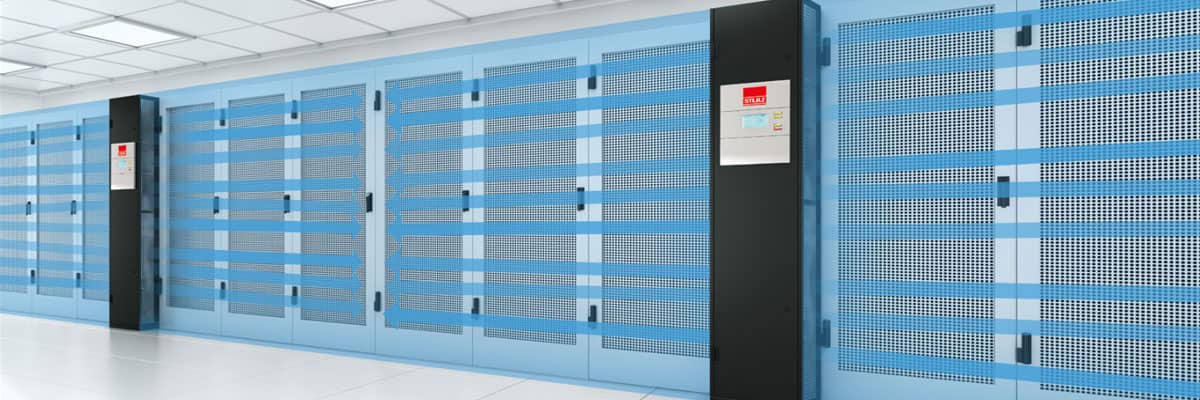

CyberRow – The in-line air conditioning unit with innovative air conduction.

In the CyberRow, innovative horizontal air conduction has been enhanced with state-of-the-art technology that works with power, flexibility and efficiency – directly at the rack. Fluctuating server rack loads, space restrictions, lack of a raised floor, existing high-density server technology – these are exactly the cases from practice for which CyberRow was developed. The air conditioning unit is positioned directly between the racks. The resulting short air conduction routes contribute to the high efficiency of these units. Moreover, the option of Indirect Dynamic Free Cooling offers the greatest potential savings worldwide.

Advantages at a glance

Suitable for data centers with or without

raised floor

• Can be used with racks from any manufacturer

• Targeted cooling of high-density racks

• Each unit can cool up to six server cabinets

• Optimized cooling air pattern creates a virtual

containment

• Indirect Dynamic Free Cooling for maximum

potential savings

• Innovative technology and high-quality

components keep energy consumption

to a minimum

• Two mutually independent setpoints ensure

precise temperature control

• Up to five independent, variable-speed EC fans

for need based cooling in three horizontal zones

• Variable-speed EC compressor for precise

cooling capacity and integrated soft start

• Easy maintenance thanks to access from the

front and rear of the unit

Flexible and efficient –

with and without containment.

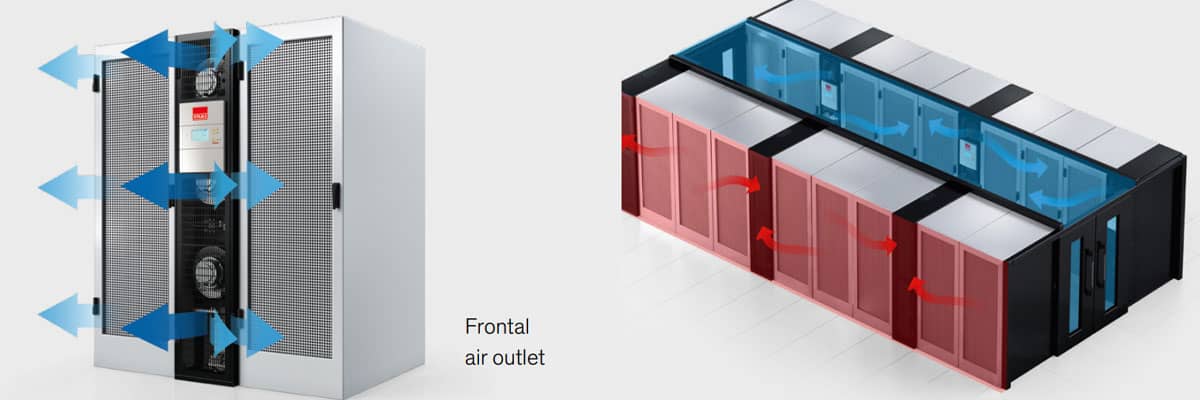

The red areas – around the EC fans – show that the fans emit the cold air at a very high speed (approx. 9-11 m/s) at the outlets. However, this is only the case as long as the air is in the housing. The partitions installed between the EC fans channel the air flow and the air baffles at the outlet ensure uniform distribution across the entire height of the racks.

The virtual containment can be clearly seen in this picture. The air flow virtually sticks to the server racks and there is no air turbulence. The cold air takes a direct route to the front of the server racks.

With the CyberRow, STULZ offers an efficient air conditioning solution that is positioned directly between the racks in the server room. Thanks to the innovative horizontal air conduction, the supply air is directed to the server racks and forms a cold air curtain in front of them. There is no air turbulence, which means that up to six server racks can be cooled simultaneously. The units are especially easy to integrate and enable hot and cold aisle containments – as well as virtual containments – to be achieved extremely quickly.

Virtual containment

The high efficiency of the CyberRow units is possible due to their proximity to the server rack: their unique air conduction prevents hot and cold air from mixing. This air conduction is like a virtual containment, dispensing with the need to build actual containments.

The virtual containment can be clearly seen in this picture. The air flow virtually sticks to the server racks and there is no air turbulence. The cold air takes a direct route to the front of the server racks.

The red areas – around the EC fans – show that the fans emit the cold air at a very high speed (approx. 9-11 m/s) at the outlets. However, this is only the case as long as the air is in the housing. The partitions installed between the EC fans channel the air flow and the air baffles at the outlet ensure uniform distribution across the entire height of the racks.

Cold aisle containment

CyberRow units with frontal air outlets are used for the cold aisle containment. Here, the air conditioning units no longer supply air to the neighboring racks, but to the entire cold aisle. To ensure an optimum supply of cold air, the units are positioned at an offset to one another. The containment completely stops the airflows from mixing, ensuring efficient operation.

Hot aisle containment

For a hot aisle containment, CyberRow units with side air conduction are used. Expelling the cold air sideways ensures uniform distribution along the whole length of the aisle, while the containment effectively separates the hot and cold air. The airflows are completely prevented from mixing, further enhancing efficiency.

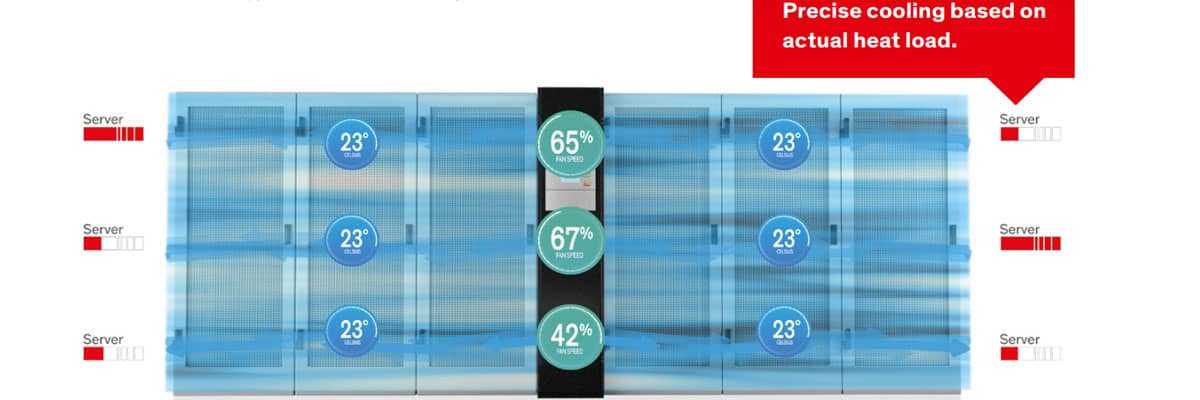

Precise cooling based on actual heat loads.

The combination of variable-speed components with fixed setpoints for the supply air and return air temperature enables precise, individual cooling in three horizontal zones. This ensures efficient and reliable cooling even during fluctuating server loads.

Individual supply air boost in three zones

Cooling capacity in each zone is individually adapted to the cooling needs of the servers. So by increasing the airflow rate, the individually required cooling capacity is delivered and perfect operation guaranteed, even with fluctuating loads. This prevents hot spots from forming,

and with no need for energy-intensive oversupply.

Fixed setpoints for maximum efficiency

Three temperature sensors on the front and three on the back of the unit, plus up to five fans, ensure precise measurement and regulation of the desired Delta T.

Individual supply air boost in three zones

Cooling capacity in each zone is individually adapted to the cooling needs of the servers. So by increasing the airflow rate, the individually required cooling capacity is delivered and perfect operation guaranteed, even with fluctuating loads. This prevents hot spots from forming,

and with no need for energy-intensive oversupply

Minimal footprint for more white space in the data center.

Maximum efficiency, precise cooling capacity and a small footprint – the CyberRow is available in three widths and two depths and ensures cost-effective and reliable operation in all situations. The individual units are positioned directly between the racks, and their compact design leaves even more space free for your IT equipment. The units are suitable for racks from any manufacturer, and are available in different depths which enables easy maintenance access from the front and rear at any rack depth.

The right system for your requirements.

Energy efficiency, capital investment, operating costs, room size, noise protection, redundancy, local climate – every project has its own specific requirements when it comes to precise air conditioning. That’s why STULZ offers you the opportunity to have the units precisely adapted to your project’s individual requirements. The right air conditioning system is a crucial factor here. The CyberRow is available in five different cooling systems, to help you achieve the ideal balance between investment, operating costs and energy efficiency.

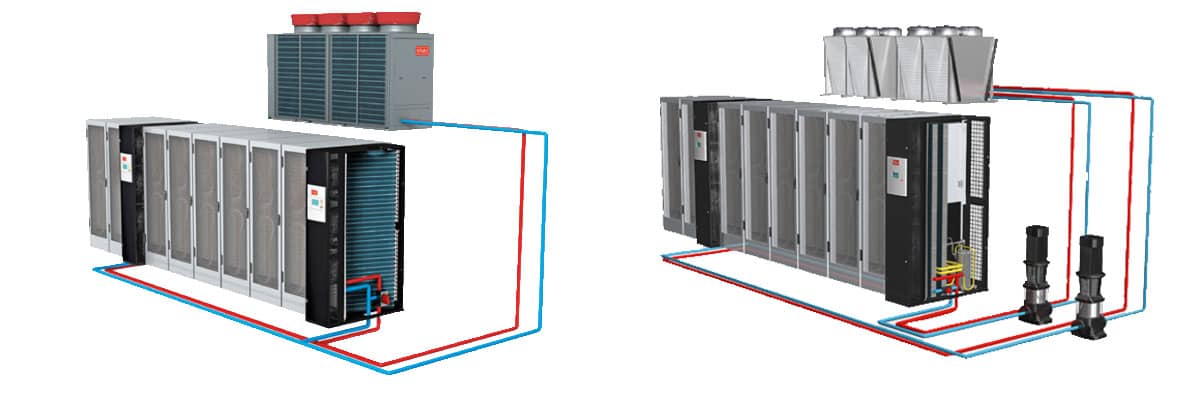

Air-cooled system based on the direct evaporator principle (A/AS)

Heat is extracted from the room air as it flows through the evaporator, and is then transferred to the refrigerant. The air conditioning unit and condenser are connected to one another by a closed refrigerant circuit. The refrigerant emits the heat to the outside air via the air-cooled condenser.

Water-cooled system based on the direct evaporator principle (GS)

Our water-cooled system works like the air-cooled system, with one difference: the heat from the refrigerant circuit is transferred to a cooling water circuit via a brazed plate condenser integrated in the air conditioning unit. This way, the amount of refrigerant required is low. The heat in the cooling water circuit is then discharged into the outside air via an external dry cooler.

Hybrid Free Cooling system with dynamic switching operation and control (GES)

This system functions like the GS system, but additionally features an integrated Free Cooling coil. This way, energyintensive compressor cooling can be wholly or partially dispensed with at low or temperate outside temperatures. The heat is transferred directly to the cooling water circuit by the integrated Free Cooling coil, and discharged into the outside air via an external dry cooler.

Indirect Dynamic Free Cooling

The GES system features dynamic switching operation and control, which guarantees reliable and efficient operation. The combination of Indirect Free Cooling and variable-speed components enables precise cooling adapted to the current heat load, and cuts overall energy consumption to a minimum.

Chilled water systems (CW/CW2)

The air conditioning unit with CW system manages without a refrigerant circuit of its own, but requires a separate chiller. The air conditioning unit and chiller are connected to one another by a closed water-glycol circuit. For high-availability systems, the CW2 system offers a redundant chilled water supply by connecting one air conditioning unit to two chilled water circuits.

Data sheet

- 4. Monitoring function

- Modbus

Snmp - 4. Power of Inrow

- 30kw

- 4. Cooling capacity

- 20~26 kw

- 4. Water in

- 7℃

- 4. Volume fluid flow

- 4.67 (1.3) / 20.6 m3 /h (l/s

10.67 (3.0) / 47.0 m3 /h (l/s) - 4. Power consumption

- 380V 3Ph-50Hz

- 4. Fan quantity

- 5

- 5. Depth

- 600~1200mm

- 5. Monitoring function

- Modbus

On touch

Snmp - 5. Touch screen LCD

- Yes

- 5. Temp - humidity control

- Up to 4 sensors

Specific References

No customer reviews for the moment.