EDGE-9 is a data center platform fully made in the United States, which includes Inrow equipment and racks in a complete package. The package can be easily assembled at the destination to create a complete and intelligent data center space. Therefore, all mechanical and thermodynamic parameters and ventilation standards have been observed completely. The width of the corridors is 1000 to 1200 mm in this package. EDGE-9 platform is designed with the aim of increasing productivity and reducing energy consumption in data center. One of its prominent features is the energy efficient cooling system. Using advanced and fully intelligent cooling technologies, EDGE-9 can prevent the rise in temperature and energy costs. By using smart cooling systems and accurate temperature management, EDGE-9 platform guarantees the most optimal conditions for cooling the data center, preventing excessive energy consumption, and monitoring all important parameters in BMS remotely.

The World of High-Tech at Your Fingertips: Fast, Easy, and Smart

The EDGE-9 solution is designed pre-configured from the factory with built in intelligence and energy efficient LX cooled InRows for rapid deployment and expert installation

Peace of mind is provided by an on-board environmental and security monitoring system. Real time alarms and alerts which can be viewed via a WebUI, so you know what’s going on and see who’s coming and going 24/7. Advanced configurations are available for enhanced levels of security and redundancy.

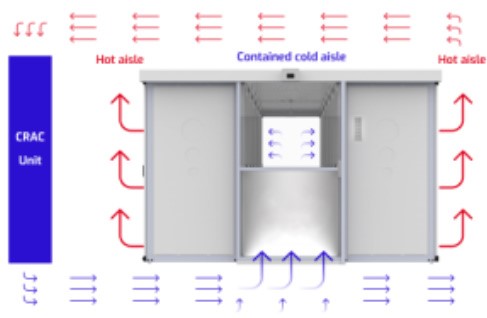

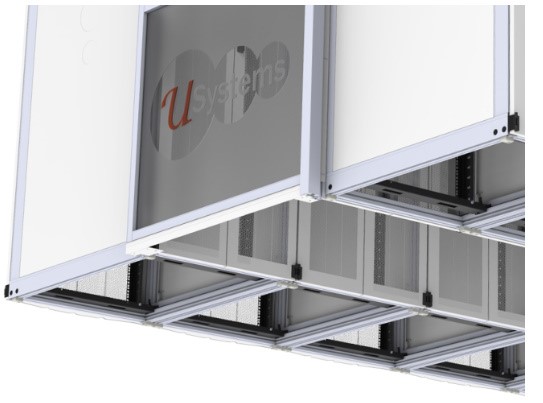

Many years of innovation and experience accumulated at USystems producing cutting edge data center solutions has been channelled into developing the most effective and efficient aisle containment systems currently available. Thermodynamically advanced, cost and energy efficient, our solutions incorporate Horizontal (flat roof) and Vertical solutions spanning hot aisle or cold aisle options all of which improve cooling efficiencies specific to your data center requirements. Each style of containment can be designed around multiple height cabinets without affecting thermal performance.

Benefits

- Up to 60% energy savings

- Thermodynamically advantageous

- Enhanced efficiency

- Hot or cold aisle versions

- Cost effective

- Low-maintenance

- Custom built

- Quick and easy installation

- Modular

- Retrofittable

- Re-locatable

- Expandable

Horizontal Aisle Containment

Aisle Air Containment fully encases the corridor with a rigid enclosure which maximises the efficient use of cold air being fed in through the raised floor. The corridor remains light as light transmission (LUX) from the data center is let in through the lightweight transparent ceiling panels which have a transparency of an impressive 88%.

Drop-Out Ceiling Panels beneath Sprinklers

Drop-out ceiling panels can be installed beneath fire sprinklers. When exposed to heat from a developing fire, drop-out ceiling panels soften, distort, and fall from the ceiling grid. Heat from the growing fire activates the sprinkler which, unimpeded by the panels, controls or extinguishes the fire.

- They offer a visually uncluttered appearance.

- They provide protection for the sprinklers – making them less prone to accidental knocks, tampering, and the potential water damage that can result.

- They simplify sprinkler design at clouds and other design features as the sprinklers are located above the dropped ceiling.

- They’re cost effective as they eliminate the need to “drop” (lower) the sprinklers, make sprinkler positioning simple so installers only make one trip instead of two, allow for the use of less costly, non-appearance grade sprinklers, and eliminate the need for trim rings/escutcheons.

Door Options

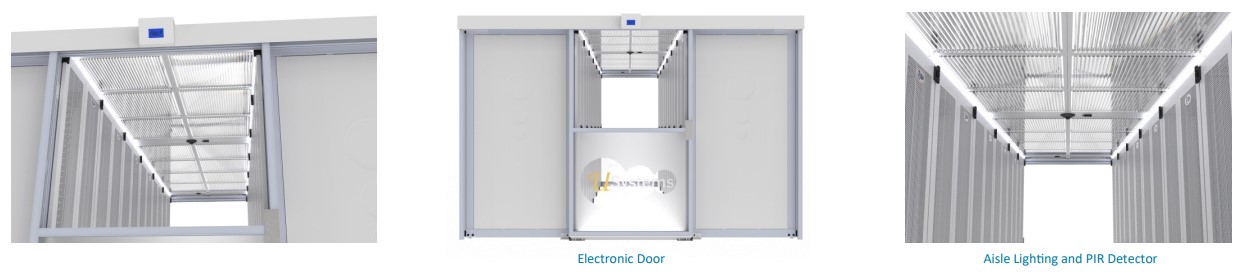

Electronic door

Outstanding user convenience and unique operational behaviour characterize the automatic sliding door operator. The door is magnetically driven and therefore silent in operation. Additionally the drive method allows for unparalleled levels of safety for the user.

Manual door

The manual door option is a state of the art sliding door closer with a hold open facility and fully adjustable damper system as standard. This ultra smooth and superbly quiet sliding door closer provides the very best quality for your application.

Vertical aisle containment lighting

The aisle beacon is controlled by a BT10 universal interface module which takes an input from the 100v loudspeaker circuit on the building fire alarm. The BT10 and a 24v relay are mounted in a Beacon Box assembly (CC6-0100-AP). The beacon is installed in the central service panel of the aisle. The customer is responsible for arranging connection of the 110v line input from the fire alarm system.

- Operation Temperature: -20˚/+50˚C

- Light Source: Chip LED

- Light Color: Natural White (3800-4200 K)

- Beam Angle: 120˚ without lens

- Light Efficacy: 105 lm/W

- Operation Voltage: 100-240V 50/60Hz.

- Power Consumption (W): 10W/m

- Dual voltage 12/24V (10-30Vdc)

- Bright, intense Xenon flash

- No moving parts – maintenance free

- Low power consumption

- 3,000 hours tube life

- Operating temperature -30°C to -55°C

Rack - In Row

Data sheet

- 4. Monitoring function

- Modbus

Snmp - 4. Type of Inrow

- Water

- 4. Power of Inrow

- 30kw

60kw - 4. Cooling capacity

- 300W

600W - 4. Configuration type

- HAC

- 4. Air flow

- 8535 m 3 /h

- 4. Water in

- 14℃

18℃

20℃ - 4. Water out

- 20℃

25℃

30℃ - 4. Volume fluid flow

- 4.23 (1.2) / 18.6 m3 /h (l/s

4.67 (1.3) / 20.6 m3 /h (l/s

7.14 (2.0) / 31.5 m3 /h (l/s)

7.77 (2.2) / 34.2 m3 /h (l/s)

9.88 (2.7) / 43.5 m3 /h (l/s)

10.67 (3.0) / 47.0 m3 /h (l/s) - 4. Power consumption

- 230V 50Hz

- 4. Fan quantity

- 6

- 5. Size of rack

- 42U

47U

48U

52U

Specific References

No customer reviews for the moment.