Control system

The PowerCommand control system is an integrated microprocessor based generator set control system providing voltage regulation, engine protection, alternator protection, operator interface and isochronous governing.

AmpSentry – Includes integral AmpSentry protection, which provides a full range of alternator protection functions that are matched to the alternator provided.

Power management – Control function provides battery monitoring and testing features and smart starting control system.

Advanced control methodology – Three phase sensing, full wave rectified voltage regulation, with a PWM output for stable operation with all load types.

Communications interface – Control comes standard with PCCNet and Modbus interface.

Regulation compliant – Prototype tested: UL, CSA and CE compliant.

Service - InPower PC-based service tool available for detailed diagnostics, setup, data logging and fault simulation.

Reliable design – The control system is designed for reliable operation in harsh environment.

Multi-language support

Operator panel features

Operator panel features – The operator panel, in addition to the alternator, displays the Utility/AC Bus data.

Operator/display functions

- 320 x 240 pixels graphic LED backlight LCD

- Auto, manual, start, stop, fault reset and lamp test/panel lamp switches

- Alpha-numeric display with pushbuttons

- LED lamps indicating genset running, remote start, not in auto, common shutdown, common warning, manual run mode, auto mode and stop

Paralleling control functions

- Digital frequency synchronization and voltage matching

- Isochronous kW and kvar load sharing controls

- Droop kW and kvar control

- Sync check

- Extended paralleling (Peak Shave/Base Load)

- Digital power transfer control (AMF) provides load transfer operation in open or closed transition or soft (ramping) transfer mode

Features & Benefits

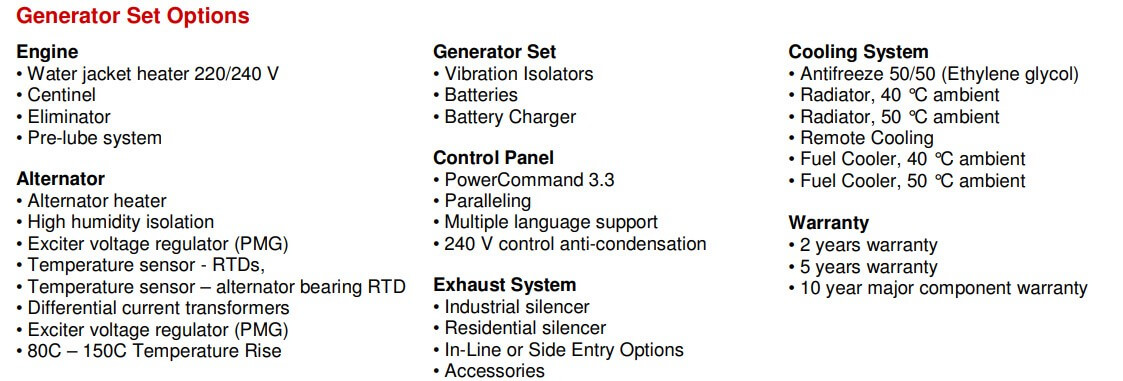

Cummins heavy-duty engine - Rugged 4- cycle industrial diesel delivers reliable power, low emissions and fast response to load changes.

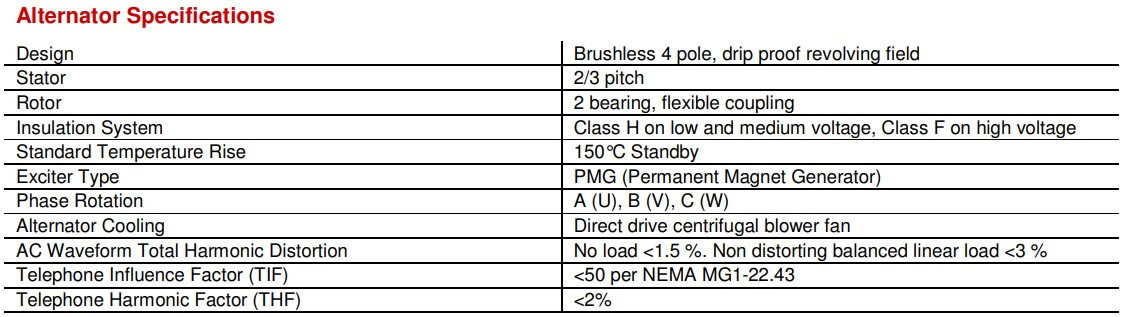

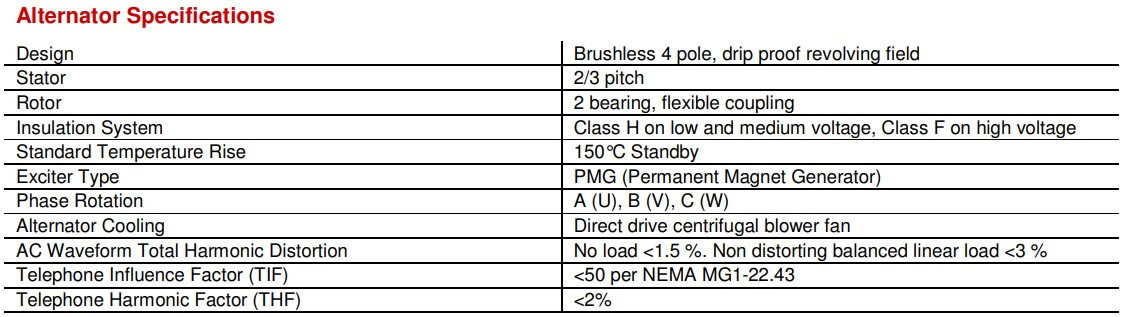

Permanent Magnet Generator (PMG) - Offers enhanced motor starting and fault clearing short circuit capability.

Alternator - Several alternator sizes offer selectable motor starting capability with low reactance 2/3 pitch windings; low waveform distortion with non-linear loads, fault clearing short-circuits capability, and class F or H insulation.

Cooling system - Optional remote mounted cooling system, designed and tested for rated ambient temperatures, offers maximum flexibility for facility design requirements.

Control system - Standard PowerCommand® electronic control provides total system integration including remote start/stop, precise frequency and voltage regulation, alarm and status message display, AmpSentry protection, output metering, auto-shutdown at fault detection and NFPA 110 Level 1 compliance.

NFPA - The genset accepts full rated load in a single step in accordance with NFPA 110 for Level 1 systems.

Warranty and service - Backed by a comprehensive warranty and worldwide distributor network.

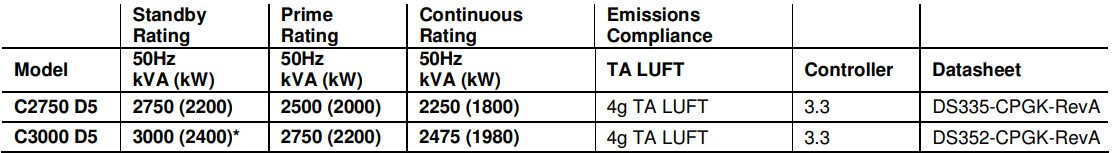

Specifications

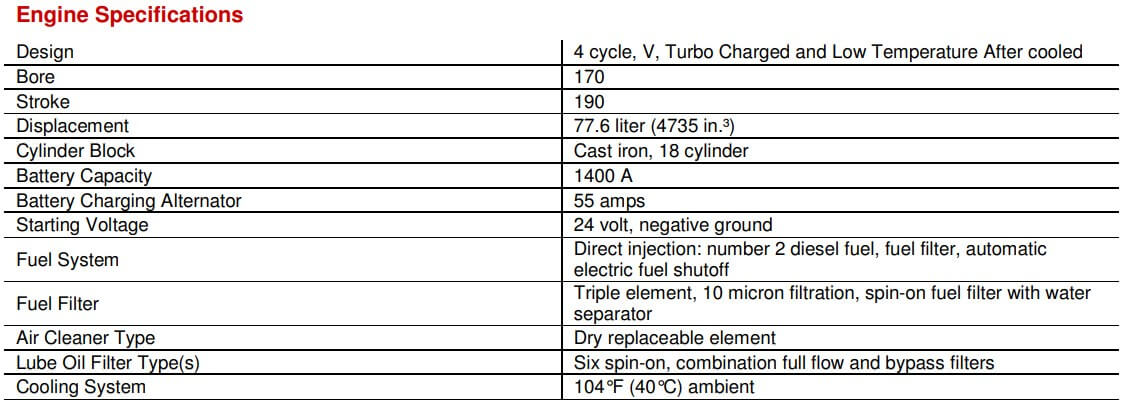

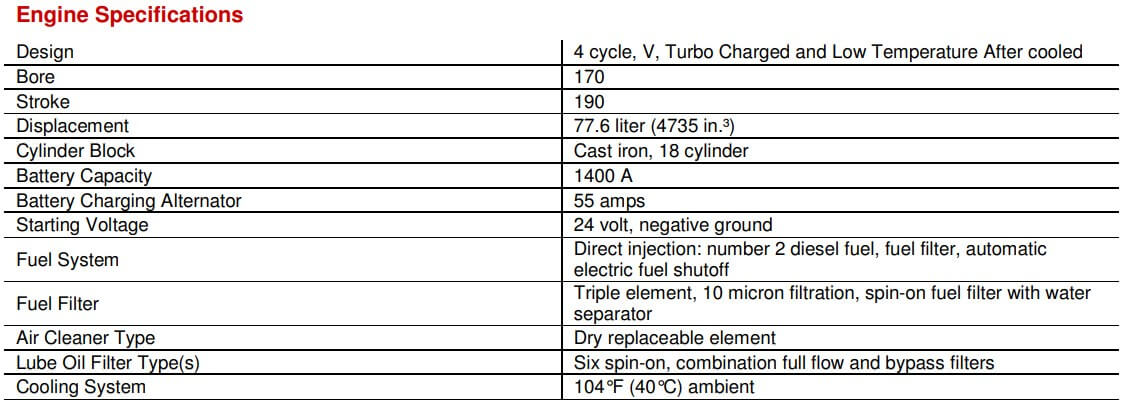

- Design: 4 cycle, V, turbo charged and low temperature after-cooled

- Bore: 170

- Stroke: 190

- Displacement: 77.6 L (4735 in3)

- Cylinder block: Cast iron, 18 cylinder

- Battery capacity: 1400 A

- Battery charging alternator: 55 amps

- Starting voltage: 24-volt, negative ground

- Fuel system: Direct injection: number 2 diesel fuel, fuel filter, automatic electric fuel shutoff

- Fuel filter: Triple element, 10 micron filtration, spin on fuel filter with water separator

- Air cleaner type: Dry replaceable element

- Lube oil filter type(s): Four spin-on, combination full flow and bypass filters

- Cooling system: 104 ºF (40 ºC) ambient