بشكل عام، يکون Cummins QSK95 مولدًا قويًا ومع قدرات تقنية عالية وهو مناسب للاستخدام في المدارس، والمستشفيات، والصناعات الكبيرة والبيئات الصناعية.

The generator has a low volume audio system that reduces the volume, and prevents excessive noise production. Overall, the Cummins QSK95 is a powerful generator with high technical capabilities that is suitable for use in schools, hospitals, and large industrial places.

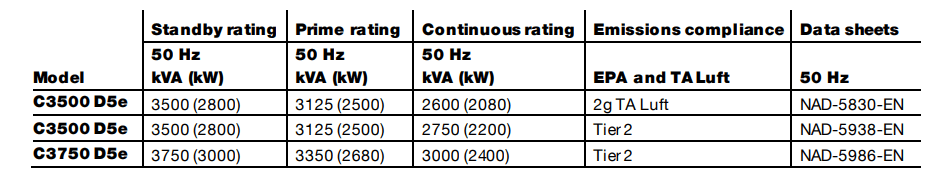

Cummins Power Generation commercial generator sets are fully integrated power generation systems providing optimum performance, fuel economy, reliability and versatility for stationary standby, prime and continuous power applications.

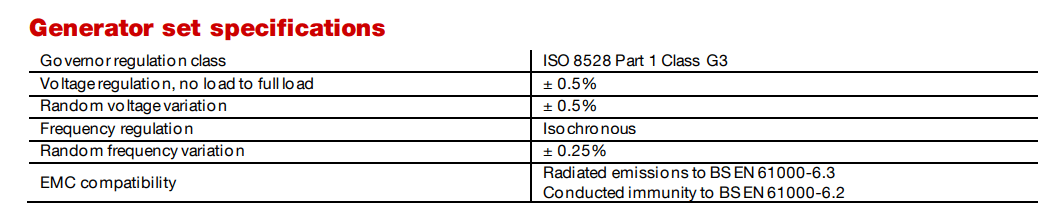

An integrated microprocessor based generator set control system providing voltage regulation, engine protection, alternator protection, operator interface and isochronous governing. Refer to document S-1570 for more detailed information on the control.

Amp Sen try – Includes integral Amp Sen try protection, which provides a full range of alternator protection functions that are matched to the alternator provided.

Power management – Control function provides battery monitoring and testing features and smart starting control system.

Advanced control metho do logy – Three phase sensing, full wave rectified voltage regulation, with a PWM output for stable operation with all load types.

Communications interface – Control comes standard with PCCNet and Modbus interface.

Regulation compl iant – Prototype tested: UL, CSA and CE compliant.

Service - InPower™ PC-based service tool available for detailed diagnostics, setup, data logging and fault simulation.

Easily upgradeable – PowerCommand controls are designed with common control interfaces.

Rel iable design – The control system is designed for reliable operation in harsh environment.

Multi-language support

Operator panel features

Operator/display functions

- Displays paralleling breaker status

- Provides direct control of the paralleling breaker

- 320 x 240 pixels graphic LED backlight LCD

- Auto, manual, start, stop, fault reset and lamp test/panel lamp switches

- Alpha-numeric display with pushbuttons

- LED lamps indicating genset running, remote start, not in auto, common shutdown, common warning, manual run mode, auto mode and stop

Para lleling control functions

- First Start Sensor System selects first genset to close to bus

- Phase Lock Loop Synchronizer with voltage matching

- Sync check relay

- Isochronous kW and kVar load sharing

- Load govern control for utility paralleling

- Extended Paralleling (baseload/peak shave) Mode

- Digital power transfer control, for use with a breaker pair to provide open transition, closed transition, ramping closed transition, peaking and base load functions.

Other control features

- 150 watt anti-condensation heater

- DC distribution panel

- AC auxiliary distribution panel

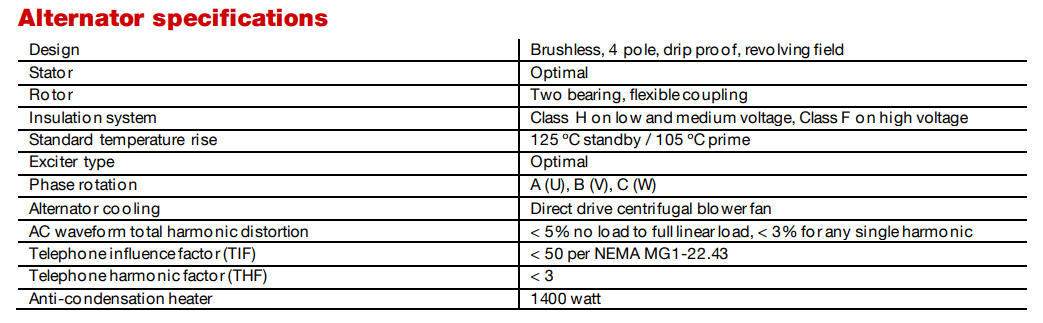

Alternator data

- Line-to-neutral and line-to-line AC volts

- 3-phase AC current

- Frequency

- kW, kvar, power factor kVA (three phase and total)

- Winding temperature

- Bearing temperature

Engine data

- DC voltage

- Engine speed

- Lube oil pressure and temperature

- Coolant temperature

- Comprehensive FAE data (where applicable)

Other data

- Genset model data

- Start attempts, starts, running hours, kW hours

- Load profile (operating hours at % load in 5% increments)

- Fault history

- Data logging and fault simulation (requires InPower)

- Air cleaner restriction

- Exhaust temperature in each cylinder

Standard control functions

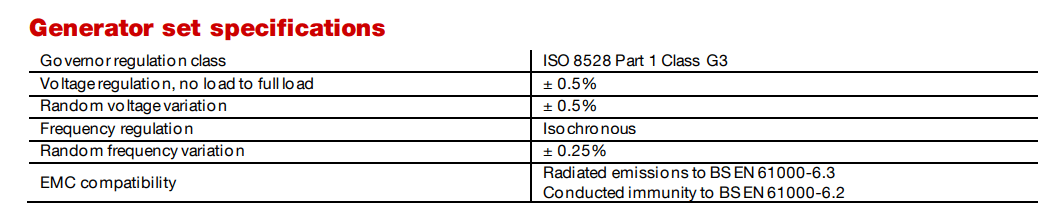

Digita l governing

- Integrated digital electronic isochronous governor

- Temperature dynamic governing

Digita l voltage regulation

- Integrated digital electronic voltage regulator

- 3-phase, 4-wire line-to-line sensing

- Configurable torque matching

AmpSentry AC protection

- AmpSentry protective relay

- Over current and short circuit shutdown

- Over current warning

- Single and three phase fault regulation

- Over and under voltage shutdown

- Over and under frequency shutdown

- Overload warning with alarm contact

- Reverse power and reverse var shutdown

- Field overload shutdown

Engine protection

- Battery voltage monitoring, protection and testing

- Overspeed shutdown

- Low oil pressure warning and shutdown

- High coolant temperature warning and shutdown

- Low coolant level warning or shutdown

- Low coolant temperature warning

- Fail to start (overcrank) shutdown

- Fail to crank shutdown

- Cranking lockout

- Sensor failure indication

- Low fuel level warning or shutdown

- Fuel-in-rupture-basin warning or shutdown

- Full authority electronic engine protection

Control functions

- Time delay start and cool down

- Real time clock for fault and event time stamping

- Exerciser clock and time of day start/stop

- Data logging

- Cycle cranking

- Load shed

- Configurable inputs and outputs

- Remote emergency stop

Options

- Additional configurable inputs and outputs

Features & Benefits

Cummins heavy-duty engine - Rugged 4-cycle industrial diesel delivers reliable power, low emissions and fast response to load changes.

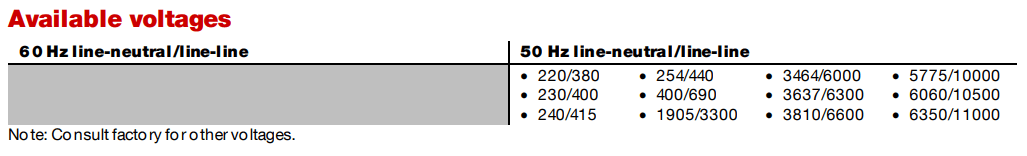

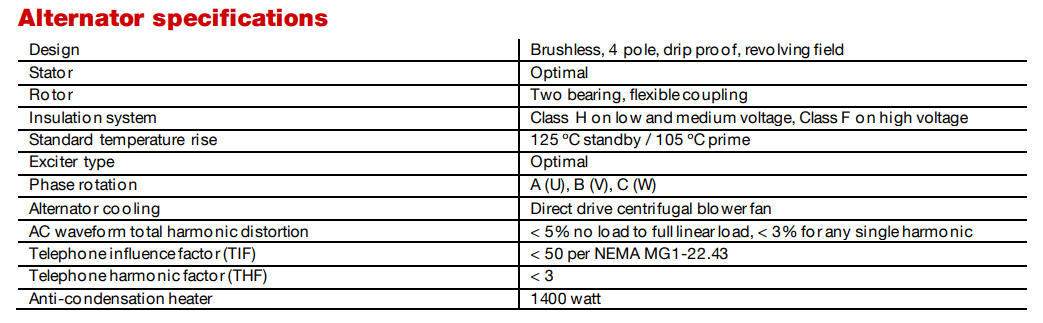

Alternator - Several alternator sizes offer selectable motor starting capability with low reactance windings, low waveform distortion with non-linear loads and fault clearing short-circuit capability.

Control system - The PowerCommand® digital control is standard equipment and provides total genset system integration including automatic remote starting/stopping, precise frequency and voltage regulation, alarm and status message display, AmpSentryTM protective relay, output metering and auto-shutdown.

Cooling system - Standard and enhanced integral set-mounted radiator systems, designed and tested for rated ambient temperatures, simplifies facility design requirements for rejected heat. Also optional remote cooled configuration for non-factory supplied cooling systems.

Warranty and service - Backed by a comprehensive warranty and worldwide distributor network.

NFPA - The generator set accepts full rated load in a single step in accordance with NFPA 110 for Level 1 systems.

Uptime Compliant - Meets the requirement of a Tier III and IV data center site by being rated to run for unlimited hours of operation when loaded to 'N' demand for the engine generator set.

Data Center Continuous (DCC) – Applicable for supplying power continuously to a constant or varying electrical load for unlimited hours in a data center application.

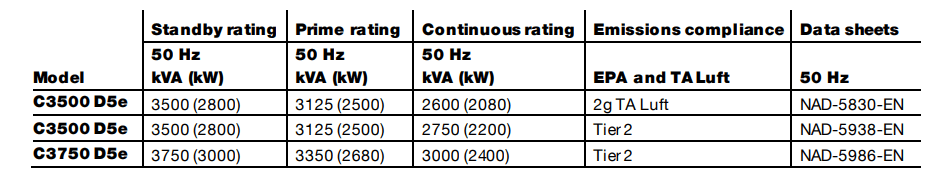

Specifications

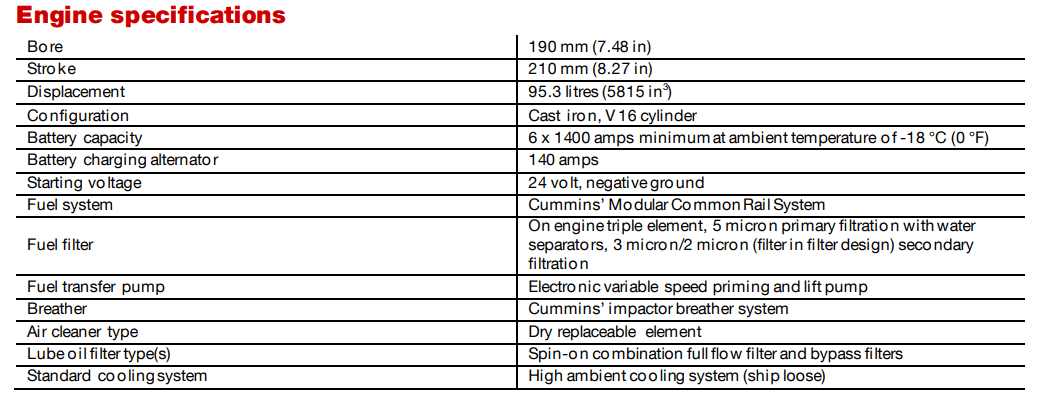

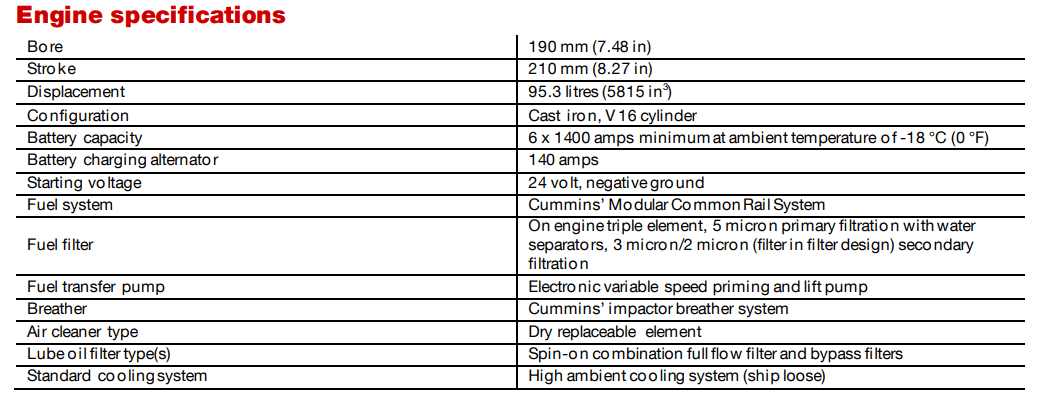

- Bore: 190 mm (7.48 in)

- Stroke: 210 mm (8.27 in)

- Displacement: 95.3 L (5815 in3)

- Configuration: Cast iron, V 16 cylinder

- Battery capacity: 6 x 1400 amps minimum at ambient temperature of -18 °C (0 °F)

- Battery charging alternator: 140 amps

- Starting voltage: 24 volt, negative ground

- Fuel system: Cummins modular common rail system

- Fuel filter: On engine triple element, 5 micron primary filtration with water separators, 3 micron/2 micron (filter in filter design) secondary filtration.

- Fuel transfer pump: Electronic variable speed priming and lift pump

- Breather: Cummins impactor breather system

- Air cleaner type: Unhoused dry replaceable element

- Lube oil filter type(s): Spin-on combination full flow filter and bypass filters

- Standard cooling system: High ambient cooling system (ship loose)