دیزل ژنراتور موديل C2000D5P من سلسلة QSK60 من مصنع كومنز. المحرك الدقيق لهذا الديزل جينيريتور هو QSK60-G4، وهو محرك 16 سلندر رباعي الأشواط. اختارت كومنز مولد الديزل هذا بنوع S7L1D-G4 من ستامفورد. يتم استخدام وحدة التحكم PowerCommand 3.3من كومنز في ديزل جينيريتور C2000D5P لمراقبة العمليات. الجهد الناتج لهذا الديزل جينيريتور هو 415 فولت، وتردد عمله هو 50 هرتز. يجب الإشارة إلى أن الديزل جينيريتور C2000D5P هو جهاز ثلاثي الأطوار. الديزل جينيريتور C2000D5P من نوع OPEN TYPE.

عالم التكنولوجيا في متناول يدك: سريع وسهل وذكي

Reliable and Durable

Cummins® ‘QSK60 series’ (Quantum leap in product technology) diesel engine with strong regrindable crankshaft, high strength connecting rod, high pressure injection full authority electronic fuel system, 2 pump 2 loop coolant system. ‘QSK60 series’ generating sets are more reliable and durable. Engines have clocked millions of hours operating in some of the world’s most demanding conditions. Current engines are regularly upgraded with new technologies for better performance and economy. The ultimate proof of superior performance and reliability is the fact that Cummins® manufactures these engines in India.

Unmatched Warranty

Cummins® ‘QSK60 series’ diesel engine generating sets are a truly cost effective solution to long term power need backed by industry best, 2 years / 5000 hrs warranty, for the entire generating set. With superior experience in technology , design capability, commitment, reliability and quality we offer an unmatched 5 years or 5000 hours (including above 2 years) warranty coverage on 5 critical components (5C) of the engine – Cylinder Head, Camshaft, Crankshaft, Cylinder Block, Connecting Rod against manufacturing defect ( 5C warranty is offered only for India source product.

Cummins Advantage

Special features of Cummins® ‘K50 series’ engines like ESTC (Electrical Step Timing Controls) injectors, low temperature aftercooler, square cumbustion chamber, optimised turbocharging and precision heavy duty camshaft make these engines the ultimate in exceptional fuel efficiency all across the operating range.

Single Source Power Assurance

Design, manufacture and testing of engine, alternator and other accessories is done by Cummins Group of companies for optimum performance and is backed by a countrywide product support network with a single source responsibility for the entire package.

Standard Scope

Engine: Cummins® ‘QSK60 series’ full authority electronic injection, water cooled engine, 16 cylinder, 4 stroke, rated at 1500 RPM, conforming to ISO 3046 /IS 13018 has the following specifications:

• Cummins Full Authority electronics

• Cummins HPI injectors

• Cummins turbocharger, pulse tuned exhaust manifold, stainless steel exhaust flexible connections (4 Turbos)

• Radiator or heat exchanger, coolant inhibitor

• Plate type lube oil cooler

• Outboard aftercoolers

• Full flow paper element filters - fuel, lube oil and bypass

• Dry type replaceable paper element air cleaner with restriction indicator

• Flywheel housing & flywheel to suit single bearing alternator

• Starting motor – Electric,

• battery charging alternator

• Cummins PowerCommand® microprocessor based genset controller

• First fill lube oil

Alternator:

Stamford brushless alternator

• Seperately excited, self-regulated

• Salient pole revolving field

• Single / double bearing

• VPI epoxy impregnated insulation technology

• Re-greasable deep groove Single bearing

• Excitation - PMG based brushless

• Space heater & RTD & BTD - (without scanner)

Accessories:

• Silencer suitably optimized to reduce noise

• Sturdy base rail

• 990 ltrs. free standing fuel tank

•Batteries with connecting leads and terminals

Optionals

Engine:

Heat exchanger, No cool, 398 lts. oil pan

Control Panel: PC3.3

-Bargraph For PC3.3 Panel with kW, Power factor, Frequency,Current, Voltage -Remote HMI

AMF control panel, Battery charger, Remote/Auto start panel, Auto/ Manual synchronizing panel, Audio/Visual annunciation for faults, Auxiliary output relays and remote annunciators

Control panel:

PowerCommand® PC 3.3 with MLD

The PowerCommand® control system is an integrated microprocessor based generator set control system providing voltage regulation, engine protection, alternator protection, operator interface and isochronous governing.

AmpSentryTM

– Includes integral AmpSentryTM protection, which provides a full range of alternator protection function which are matched to the alternator provided.

Power Management

– Control function provides battery monitoring, testing and a smart starting control system.

Advanced Control Methodology

– Three phase sensing, FET based full wave rectified voltage regulation and a PWM output for stable operation with all load types.

Communications Interface

– Control comes standard with PCCNet and Modbus interface.

Regulation Compliant

– Prototype tested: UL, CSA and CE compliant.

Service

- InPower™ PC-based service tool available for detailed diagnostics, setup, data logging and fault simulation.

Reliable Design

– For reliable operations in harsh environment.

Multi-language support

Independent of PC/ laptop for setting up

Operator panel features

Operator Panel Features

– The operator panel, in addition to the alternator, displays the Utility/ AC Bus data.

Operator/ Display Functions

• 320 x 240 pixels graphic LED backlight LCD with bar graph for displaying electrical parameters

• Auto, manual, start, stop, fault reset and lamp test/panel lamp switches

• Alpha-numeric display with pushbuttons

• LED lamps indicating genset running, remote start, not in auto, common shutdown, common warning, manual run mode, auto mode and stop

Paralleling Control Functions

• Digital frequency synchronization and voltage matching

• Isochronous kW and kvar load sharing controls

• Droop kW and kvar control

• Sync check

• Extended paralleling (Peak Shave/Base Load)

• Digital power transfer control (AMF) provides load transfer operation in open or closed transition or soft (ramping) transfer mode

Alternator Data

• Line-to-neutral and line-to-line AC volts

• 3-phase AC current

• Frequency

• kW, kvar, power factor kVA (three phase and total)

Engine Data

• DC voltage

• Engine speed

• Lube oil pressure

• Coolant temperature/ low level

• Comprehensive FAE data (where applicable)

Other Data

• Genset model data

• Start attempts, starts, running hours, kW hours

• Load profile (operating hours at % load in 5% increments)

• Fault history

• Data logging and fault simulation (requires InPower)

Standard control functions

Digital Governing

• Integrated digital electronic isochronous governor

• Temperature dynamic governing

Digital Voltage Regulation

• Integrated digital electronic voltage regulator

• 3-phase, 4-wire line-to-line sensing

• Configurable torque matching

AmpSentryTM AC Protection

• AmpSentryTM protective relay

• Over current and short circuit shutdown

• Over current warning

• Single and three phase fault regulation

• Over and under voltage shutdown

• Over and under frequency shutdown

• Overload warning with alarm contact

• Reverse power and reverse var shutdown

• Field overload

Engine protection

• Battery voltage monitoring, protection and testing

• Over speed shutdown

• Low oil pressure warning and shutdown

• High coolant temperature warning and shutdown

• Low coolant level warning or shutdown

• Low coolant temperature warning

• Fail to start (over crank) shutdown

• Fail to crank shutdown

• Cranking lockout

• Sensor failure indication

• Low fuel level warning or shutdown

MLD features

• Load dependent start/stop

• Run hour equalization

• Built-in Logic

• Single point MLD setting

• System monitoring

• Master-less

• Single point remote start

• Predictive Load input

• Dedicated screens

Telematics Offerings

• Fault Code Alerts on Email & SMS

• Advisory Services

• Fuel Level Monitoring on Email & SMS

• Multiple Gensets Central Monitoring

• Automatic Reports Generation

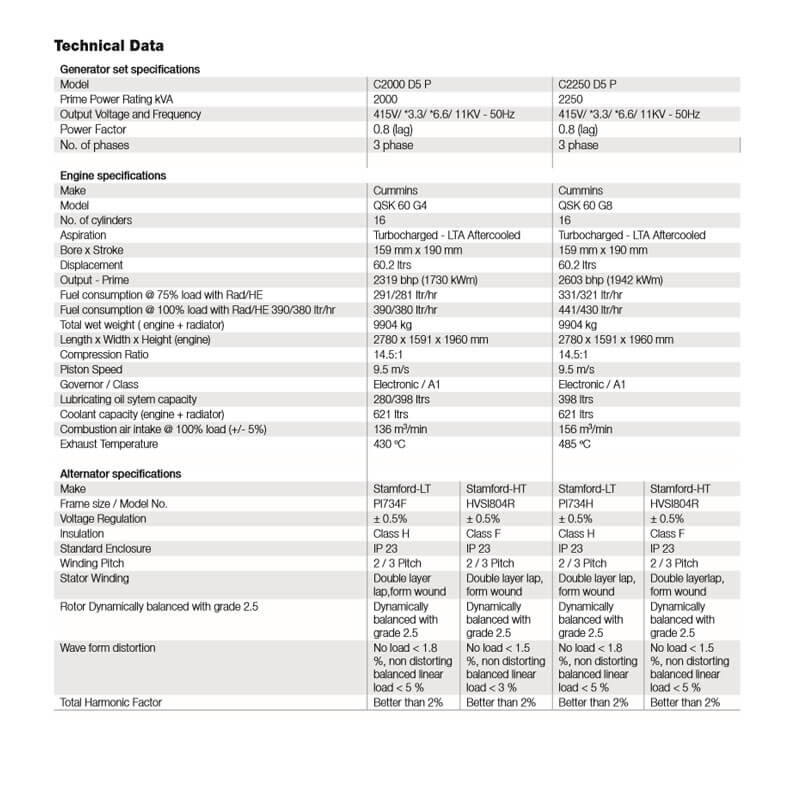

البيانات

- نظام التحكم

- PowerCommand 3.3

- الفولتية المتاحة

- (50Hz) 415 V

- Configuration

- 16 cylinder, 4 stroke

- Displacement

- 60.2 litres (3673 in3)

- التردد (هرتز)

- 50

- طاقة الخرج (kW / kVA)

- 2000KVA

- Stroke

- 190 mm (7.48 in.)

- Bore

- 159 mm (6.25 in.)

مراجع محددة

لا استعراضات العملاء في الوقت الراهن.